The APC system consists of several pallets which might be preloaded with raw product, permitting for uninterrupted machining. This automation drastically boosts production effectiveness, lessening manual dealing with and errors.

The CNC four axis machining center provides a rotary table to your worktable of the 3 axis machining center, to ensure that one particular clamping can entire the machining of the four sides from the element.

-MF CNCs present fast and correct functionality of milling machines. This Handle sequence is noted for its dependability and has become the go-to CNC System driving machine tools used in machine retailers all over the world. 0iMF Series

In search of an extensive price guidebook for different types of CNC machines? “The amount of does a CNC Charge?” could be the information in your case.

Sometimes known as a turret mill, Bridgeport-style mill, mill drill, or perhaps a drilling machine, the knee-sort vertical milling machine is a extremely adaptable piece of equipment commonly employed in numerous industries for its capability to handle many responsibilities. It can even go ahead and take location of the stand-by itself drill push. Its defining function is often a vertically adjustable worktable (the “knee”), which provides adaptability in dealing with unique dimensions and kinds of workpieces.

Metal fabrication outlets managing far more substantial parts of metal will want both comprehensive-sizing Learn more mills or greater benchtop versions. You may want a strengthened milling head over a vertical mill, or you might leap straight into a horizontal mill.

Vertical milling machines will be the go-to method for making surfaces given that they are a far more effective means of deal with milling than grinders, abrasives, and planers. Industries including automotive, aerospace, and electronics trust in these machines for making intricate parts and factors.

Fashionable mini-mills with CNC technology have amplified versatility and far more programs. In the following area, CNC technology are going to be defined in more depth.

Improved precision: The opportunity to machine various sides and angles of the workpiece without having repositioning decreases the chance of inaccuracies caused by manual handling.

G-code is definitely the most generally used programming language for CNC machines, and understanding it really is important for making successful and exact CNC plans that produce superior-high quality parts.

Will you be acquainted with the programming of CNC machining centers? CNC programming is a fancy process check here that needs prolonged-phrase practical experience for beginners.

If you plan to utilize a third-celebration CAM program to crank out your tool path plan, utilize a generic FANUC article processor and edit it to match our listing of codes.

Inside the electronics business, CNC machining centers are used to Learn more manufacture factors like heat sinks, housings and connectors, which demand limited tolerances and exact dimensions.

With a turret machine, the spindle and mattress go perpendicular and parallel for the axis, while bed milling machines only go the desk perpendicular for the axis. For that reason, most organizations favor turret machines because they keep the majority in the flexibility.

Scott Baio Then & Now!

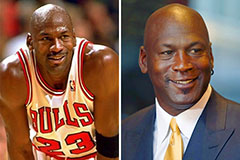

Scott Baio Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Mason Reese Then & Now!

Mason Reese Then & Now! Susan Dey Then & Now!

Susan Dey Then & Now! Richard Dean Anderson Then & Now!

Richard Dean Anderson Then & Now!